The 5 Stages of The Average Equipment Lifecycle

Blog

Table of Contents

Take Control of Your Assets

A personalized demo is just one click away.

From laptop computers in a school to medical equipment in a hospital, organizations across every industry rely on physical equipment to perform daily tasks. Though these equipment assets remain some of an organization’s largest financial investments, little attention is paid to the average equipment lifecycle. Look a little closer and you’ll see that each of these individual assets is undergoing a series of replicable equipment lifecycle stages right now. Understanding these stages and what they represent can be the key to avoiding equipment failure, unplanned downtime, and unexpected costly replacements. Read on to learn more about each of these stages—from planning to safe disposal—to extend the lifespan of your equipment assets, cut costs, and improve maintenance across your entire organization.

Key takeaways

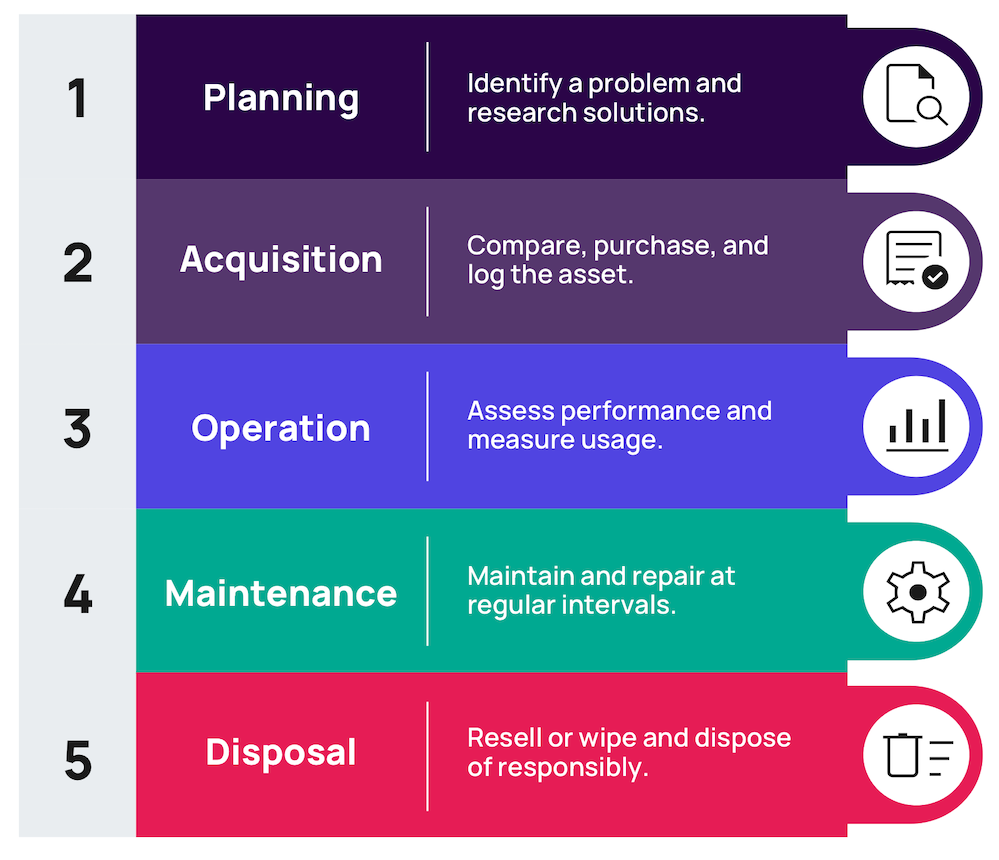

- Equipment assets have an expected lifecycle consisting of five stages.

- The five stages of the equipment lifecycle are Planning, Acquisition, Operation, Maintenance, and Disposal.

- It can take a different number of years for different types of equipment to go through the five stages depending on equipment type, wear and tear, and other factors.

- Understanding the stages of the equipment lifecycle can extend the expected useful life of your equipment assets.

What is the Average Equipment Lifecycle?

From an office chair to a delivery truck, each piece of equipment that enters your organization is there to serve a purpose. But before and after these assets are put into use, they require upfront costs related to their procurement and retirement. The equipment lifecycle refers to each step of an asset’s changing status in relation to your organization, not only the period in which it is useful. It can take different amounts of time for different types of assets to go through the equipment lifecycle stages. A good source for determining expected lifecycles is the IRS, whose recovery schedule for asset depreciation paints a picture of the minimum that each type of equipment is expected to last:

Expected life of 5 years

- Technology assets, like laptops and printers

- Vehicles, like cars, taxis, and light-use trucks

- Equipment used in construction, manufacturing, or heavy-duty industries, like forklifts

- High-tech medical equipment, like imaging machines

Expected life of 7 years

- Office furniture and fixtures, like desks and chairs

- Agriculture assets, like farming equipment

Since depreciation is a system to recover a business’s upfront investment in an asset over the course of its useful life, it is a helpful tool to determine how long each equipment type will be in use. But keep in mind that this is only a benchmark. Assets in use are subject to wear and tear that can impact their performance. Studying how assets move through equipment lifecycle stages can help prolong their useful lives.

The 5 Stages of the Equipment Lifecycle

To extend the usefulness of an organization’s assets, it’s important to understand the equipment lifecycle. All equipment assets go through each of the five equipment lifecycle stages outlined below.

1. Planning

An asset’s connection to your organization begins before it even enters your physical office. The first step is for an organization to identify a problem and research an asset that will help them solve it. The organization must make considerations for performance requirements, budget constraints, and compatibility with existing assets before deciding what to purchase.

2. Acquisition

Once the organization has decided on a piece of equipment to purchase, it’s time to consider competitive bids and negotiate terms from vendors to complete the transaction. When the asset physically makes it to the organization, it needs to be added to the organization’s inventory using an asset management system. Before it can be deployed, employees may also need to be trained on the new equipment.

3. Operation

Next comes what is ideally the longest period of the asset’s lifecycle: its useful life. During the time the equipment is in operation, an organization ought to be periodically assessing its overall performance for efficiency and making sure it is in good working order. An organization can use an asset management system to track the asset’s analytics and make sure the equipment is being used to its full potential.

4. Maintenance

Periodically during the equipment’s operational years, it will require upkeep or repairs. An organization ought to practice scheduled preventative maintenance to take an asset out of commission at predictable periods—before it breaks down and requires maintenance when you least expect it. Asset management software with a maintenance scheduling feature can automate this lifecycle stage.

5. Disposal

Finally, an organization needs to have a plan for retiring an asset at the end of its useful life. If the equipment is still valuable, an organization can choose where to sell it and for how much. If the asset holds sensitive data, there must be a plan to wipe it before disposal. If there are safety regulations that dictate when and where the asset can be disposed of, an organization ought to be aware or face penalties.

Mastering Equipment Lifecycle Management

Managing the equipment lifecycle is about more than observing an asset as it undergoes the five stages. It is also about optimizing each of the equipment lifecycle stages to make them more efficient. Investing in asset management software can help your organization stay on track of its lifecycle management.

For asset management software that addresses each step of the equipment lifecycle, look no further than Asset Panda. Our cloud-based solution allows you to manage all of your equipment data in one place so you can look up their precise details at a glance. You can track their usage and efficiency over time with our modular report generator. You can track repairs and stay on top of scheduled maintenance with our built-in scheduling tools. Our mobile app means you don’t need any new hardware and can access your asset tracking tools on the smartphone you already have. What’s more, our software is fully customizable and can be configured to work with your current technology stack.

Take Control of Your Assets

A personalized demo is just one click away.

[addtoany]

Frequently Asked Questions

What is an equipment lifecycle management plan?

An equipment lifecycle management plan is a strategy for maximizing the efficiency of every step of the equipment lifecycle. For the Operation stage, this means prolonging it; for all the others it means decreasing the time it takes.

An organization can improve efficiency by using its management plan as a general guideline for how to address each lifecycle stage. For example, it might have a standardized preventative maintenance schedule for all of its assets.

What’s the difference between preventive and reactive maintenance?

Preventative maintenance refers to regularly scheduled equipment decommissioning to check for potential issues with a piece of equipment even before there is a noticeable drop in performance. Reactive maintenance refers to unscheduled equipment decommissioning due to an observed performance issue.

Preventative maintenance is always preferred because your organization can schedule around planned repairs more easily than it can function with unexpected downtime.

How can I optimize equipment disposal for sustainability?

Optimizing equipment disposal for sustainability actually begins in the Operation stage, when organizations have the opportunity to use data analytics and scheduled maintenance to prolong an asset’s useful life, ensuring that it doesn’t undergo wear and tear quite as quickly and require replacement sooner.

Once it’s time to dispose of the equipment, organizations can partner with e-waste recycling centers or refurbishment companies in order to ensure assets are taken out of commission responsibly.

How do I calculate the lifecycle cost of equipment?

There’s a simple formula for calculating the lifecycle cost (LCC) of any piece of equipment:

LCC = Acquisition Costs + Operating Costs + Maintenance Costs + Disposal Costs - Residual Value.

Is equipment disposal unavoidable?

Unfortunately, there is no way to completely do away with equipment disposal. Wear and tear and tech obsolescence mean your organization’s assets will eventually need to be replaced. However, through responsible practices like recycling and refurbishment, you can lessen the impact on your organization—both financially and environmentally.

Related News & Press

Learn more from a solution specialist

Schedule a demo to find out how you can transform your workflows with Asset Panda Pro

Contact our team at (888) 928-6112