NEXClean Gains 4-5 Hours Per Week By Ditching Manual Asset Entry

Case Study

Get Case Study

Summary

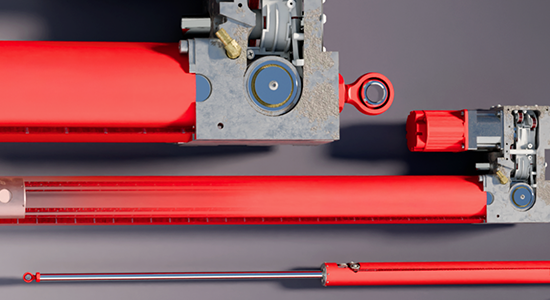

NEXClean president Dan Nestor was running into a problem; every time his cleaning technicians would perform a job for one of their medical facility clients, they would have to manually enter in a description of each piece of equipment they’d just cleaned. As expected, this system drained valuable time away from NEXClean employees who would have to factor into their schedules for each job performed the time to physically type in asset data and produce the resulting reports for their customers. NEXClean was also in need of an asset tracking system which was more mobile than their old system, since the company keeps track of thousands of pieces of equipment across multiple healthcare locations every week.

Nestor and his team chose Asset Panda as their new asset tracking and management solution, and was able to see the results they were hoping for, such as:

- Increase in productivity levels (around 4-5 hours per week, or roughly 25-30% of the time NEXClean used to spend on preparing reports for its customers)

- Real-time feedback from both technicians in the field and their healthcare customers

- Customized reports for every different service performed

Industry

Industrial Cleaning

Location

West Chester, PA

Customer Since

2016

Related resources

Learn more from a solution specialist

Schedule a demo to find out how you can transform your workflows with Asset Panda Pro

Contact our team at (888) 928-6112