Fire Department Equipment Readiness: A Guide to Tracking SCBA Cylinders and Critical Rescue Tools

Blog

Table of Contents

Take Control of Your Assets

A personalized demo is just one click away.

The tones drop at 3:00 AM. The back-step crew has swung into their jump seats, the engineer hits the Q and revs the engine, the rig clears the gates and guns it to the scene.

But wait, hang on. Are the air tanks for the Self-Contained Breathing Apparatus (SCBA) units full, tested, and up to date? Firefighters racing to a scene don’t have time to confirm that all of their fundamental safety equipment is in place and fully functioning. They just need to hear the familiar hiss-click of the SCBA regulator activating when they open the tank valve, knowing they have a steady supply of oxygen so they can focus on saving lives.

True fire department equipment readiness really is a matter of life and death. Fire teams need to know, with 100% certainty, that every tool on the rig will perform exactly as it should. And that requires a foundation of trust built on consistency, accuracy, and visibility.

But that’s hard to verify with static, error-prone documents and outdated procedures. How can fire departments meet that trust, not to mention compliance and risk mitigation, by ensuring that vital equipment is at the ready, just like firefighters are?

The Readiness Gap: Moving From Static Inventory to True Readiness

Many departments maintain inventory lists showing purchases over the last year or even the last decade. The problem with managing inventory lists in spreadsheets, even finely color-coded ones, is that they’re static, pivot table or not. Paper logs are even more limited, not to mention error-prone and vulnerable.

A spreadsheet might tell you that your station owns 50 SCBA cylinders. On paper, you look fully equipped. But can the spreadsheet tell you in real time which cylinders are flagged or due for hydrostatic testing? Can it send you an alert that a rescue tool is out for service? Or here’s one: Can you quickly confirm NFPA 1802 compliance?

There’s a big gap between static spreadsheets and verifiable readiness. For a department head, this gap presents an operational headache, as well as a massive liability. If a piece of equipment fails on the fireground and the department cannot produce a documented service history or proof of a fire apparatus inventory checklist completion, the legal and professional consequences can be severe.

To bridge this gap, departments must embrace digital systems of record that turn inventory into intelligence.

The Digital Solution for Fire Department Equipment Readiness

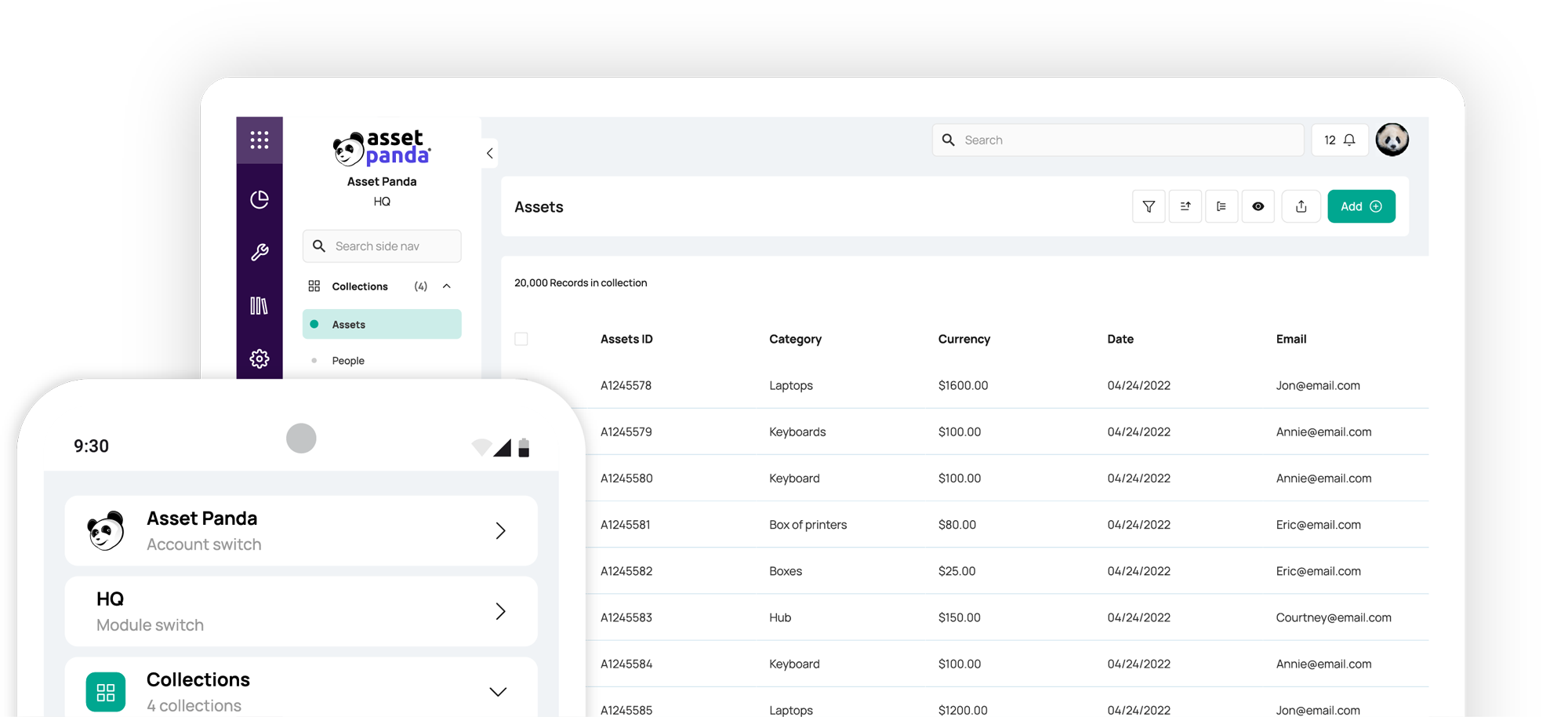

Relying on manual processes for equipment tracking creates significant risk. It’s prone to human error and doesn’t provide visibility into actual readiness. In contrast, a digital asset management system can be accessed, updated, and analyzed by anyone in the department, wherever they are.

By digitizing these records, departments gain real-time insights into things like maintenance schedules, inspection history, and operational status, ensuring every piece of equipment is accounted for and compliant with safety standards.

A digital asset management strategy moves beyond basic list making to incorporate workflows and data syncing across departments by incorporating these core functional components:

- Centralized digital registry: A single source of truth that stores a digital twin of every asset, including serial numbers, manufacture dates, and warranty info, so all data is synced and backed up.

- Mobile barcode/RFID integration: The ability to use smartphones or scanners to instantly identify equipment and log data at the side of the apparatus.

- Automated alert engine: Configurable triggers that send email or push notifications for upcoming hydrostatic tests, annual service intervals, and end-of-life retirements.

- Dynamic inspection workflows: Customizable, digital checklists that guide personnel through daily or weekly apparatus checks with mandatory fields for pass/fail status.

- Maintenance and service history: A searchable log tied to each specific asset that tracks every repair, part replaced, and technician signature for a complete audit trail.

- Role-based permissions: Controlled access that allows firefighters to log checks, while reserving the ability to edit compliance dates or delete assets for the Equipment Officer or Chief.

- Reporting and analytics dashboard: Tools to aggregate data across the entire department to visualize fleet health, compliance percentages, and total cost of ownership.

How Fire Departments Benefit from Digital Asset Management

The primary benefit of a digital transition is the move from reactive to proactive asset management. Instead of discovering a compliance issue during an audit or, worse, on the fireground, a digital system automates the tracking process and alerts leadership before a tool becomes a liability.

Moving to a digital asset management system provides many advantages for fire service operations:

- Real-time visibility: Instant access to the operational status, location, and assignment of every asset across multiple stations.

- Automated compliance: System-generated alerts for tracking hydrostatic test dates, NFPA 1802 compliance checks, and annual flow testing.

- Reduced liability: Creates an unalterable, timestamped audit trail of maintenance and inspections to protect the department in legal or NIOSH investigations.

- Increased accuracy: Requires physical interaction with equipment (via barcode or RFID scanning) to complete fire apparatus inventory checklists, minimizing human error and visibility gaps.

- Data-backed budgeting: Accurate reporting on repair costs and asset lifecycles to justify equipment replacement requests to city leadership.

- Centralized documentation: Consolidation of manuals, warranty information, and service receipts into a single, mobile-accessible digital twin for every tool.

- Streamlined workflows: Automated notifications to maintenance shops or Quartermasters the moment a tool is flagged as damaged during a shift check.

Applying Digital Asset Management in Fire Departments: Three Primary Use Cases

Here’s how digital asset management workflows can address the fire department equipment readiness gap for three primary equipment types in play.

Managing SCBA Cylinders: Mobility and Compliance

Tracking hundreds of SCBA cylinders is complex. Each bottle has a unique manufacture date, a five-year hydrostatic test requirement, and a 15-year end-of-life date. Someone has to manually review, sort, and update the spreadsheet, flag any needed maintenance, update the status of maintenance completed, and on and on. This introduces risk of missed deadlines and safety violations, and is time consuming as well.

Asset management software that includes mobile capabilities let’s equipment officers scan cylinder barcodes or RFID tags right on site using a handheld device that syncs data instantly with the main system. Officers can access the full profile of a single device to assess details like date purchased, location, and testing status, or run reports that can help with decision making, like when to budget for new units.

Here are some specific ways that asset management software can help track and manage SCBA cylinders:

- Origination certificate: Upon procurement, each cylinder’s manufacture date, serial number, and composite material type are logged into the asset management system, creating a permanent record that follows the bottle.

- Hydrostatic test triggers: The system calculates the next required test date (typically every 5 years) based on the last recorded test. Automated alerts are sent to the Quartermaster 90 days out, allowing for batching of cylinders out for testing to not deplete active truck inventory.

- Hard-stop retirement dates: For carbon-wrapped cylinders with a 15-year lifespan, the system generates a retirement report, allowing the Chief to see exactly how many bottles will expire in the next 24 months, providing a concrete number for capital budget requests.

- Fill station integration: A technician scanning a cylinder at a fill station can instantly confirm if it’s in service and within its test window. If a cylinder is flagged for a drop test or has visual damage, it can be digitally locked out of read status.

Tracking Hydraulic Rescue Tools: Maintenance Accuracy

Hydraulic rescue tools require precise service intervals to ensure high-pressure performance. Rescue tool maintenance logs are often kept in station files, making it difficult for crews to verify the tool’s service history or report mechanical issues during shift changes. And records typically aren’t unified, especially if they’re in paper form. So, information like repair history, performance, and purchase date could all be stored as a simple sheath of documents tucked together in a filing cabinet. This doesn’t help with things like tracking cumulative wear or anticipating parts replacement.

A digital asset management system unifies data from all sources, enabling any officer to log information on a tool, from anywhere, creating one centralized history for each tool.

Here are some ways in which asset management software can apply to tracking hydraulic rescue tools:

- Individualized service profiles: Every tool can be tracked as a unique asset. When a technician scans the tool, they see a Service Checklist tailored specifically to that model’s manufacturer requirements.

- Point-of-failure logging: Engineers can quickly log detailed information with dropdown menus listing specific issues, like coupler O-ring replacement or blade sharpening. This let’s a department track whether a specific tool is becoming a repair burden or if a certain brand is underperforming.

- Hour-meter tracking: For gasoline or battery-powered units, enginers can log run-time hours that trigger automated maintenance alerts for oil changes or battery health checks.

- Digital Red Tag system: If a tool fails a weekly check, it can be digitally Red Tagged in the system, which immediately changes its status to Out of Service across the entire department.

Daily Apparatus Checks: Real-Time Verification

Paper fire apparatus inventory checklists are difficult to track and offer no real-time oversight. If an item is missing or a tool fails a check, that information often doesn't reach the Chief or Equipment Officer until the end of a shift, leaving a visibility gap and introducing risk.

Building digital workflows into operations can drive daily apparatus checks with:

- Mandatory physical scans: The engineer must physically scan the barcode or RFID tag of high-value items (e.g., saws, monitors, medical bags), ensuring the crew is actually opening the compartments and verifying the presence of the gear.

- Dynamic condition reporting: Instead of just a simple checklist, digital forms can be customized to require specific data entries for critical items, such as fuel level, battery charge, or tank pressure.

- Instant out-of-service escalation: If an engineer marks a chainsaw as non-functional, the system can automatically trigger an email to the Shop Foreman and a push notification to the Shift Commander, jumpstarting the repair.

- Shift-change continuity: Incoming shifts can instantly see the notes from the previous crew, so the incoming crew is alerted to any flags before they even start their check.

A System of Record for a Culture of Readiness

Asset Panda provides a centralized digital hub for fire department equipment readiness, replacing fragmented spreadsheets with a mobile-first platform. By using barcode and RFID scanning, crews can perform inspections right at the truck, which are instantly logged and time-stamped. This ensures that critical data, from tracking hydrostatic test dates on SCBA cylinders to logging service hours on hydraulic rescue tools, is captured accurately and accessible in real-time.

Asset Panda simplifies compliance by automating administrative tasks like service triggers and fire apparatus inventory checklists. By consolidating service histories, warranty data, and operational status into a single, auditable system of record, Asset Panda helps Fire Chiefs protect their personnel, meet NFPA standards, and provide the data needed to justify municipal budget requests.

Guarantee Your Crew is Ready to Respond

Ensuring your life-saving equipment is ready is the ultimate form of asset security. Moving beyond basic inventory to a true system of record protects your personnel, your budget, and your community. Connect with an Asset Panda solution specialist to see how our unified platform can support your agency.

→ Read the Practical Guide to Securing Mission-Critical Equipment

Take Control of Your Assets

A personalized demo is just one click away.

Learn more about securing your mission-critical equipment

Learn more from a solution specialist

Schedule a demo to find out how you can transform your workflows with Asset Panda Pro

Contact our team at (888) 928-6112