Mining and Materials LIMS

Boost Productivity & Compliance

Easily manage samples and laboratory processes with Asset Panda’s materials LIMS

AI Enhanced

Improve your efficiency with the power of Asset Panda Intelligence.

Fast Time to Value

Achieve high user adoption and ROI with our intuitive interface.

Customizable Workflows

Configure the platform to match the way you already work.

Streamline workflows and increase efficiency

Optimize sample management and laboratory processes

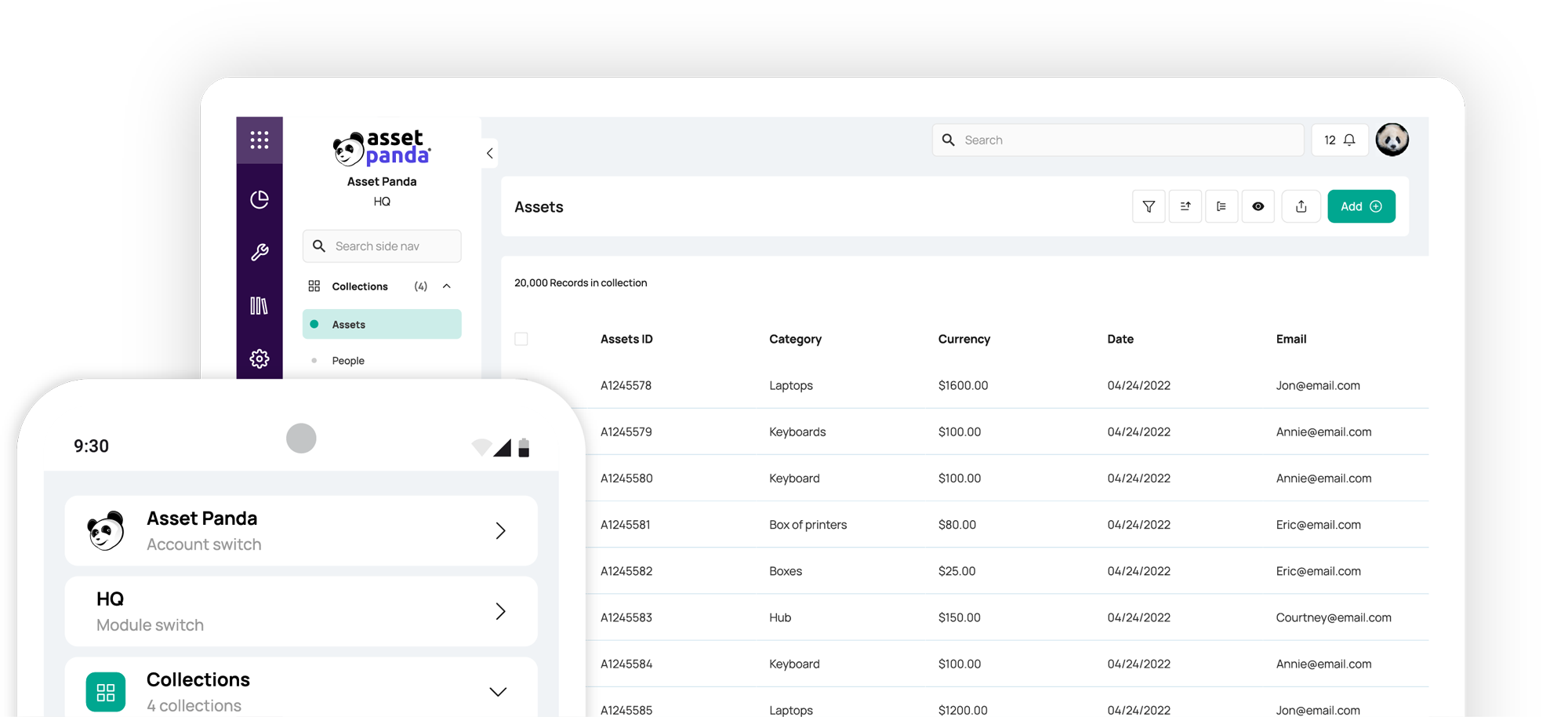

Track your samples from creation to analysis to secure the chain of custody and improve quality control in our materials LIMS. Get real-time visibility into the status and storage location of your samples and create custom notifications to alert you of sample review and expiration dates.

Further streamline your sample management processes with our mobile app with built-in barcode technology. Generate and print your own barcode labels, then instantly scan them on our mobile app to save time and improve data accuracy.

Manage everything in one convenient system

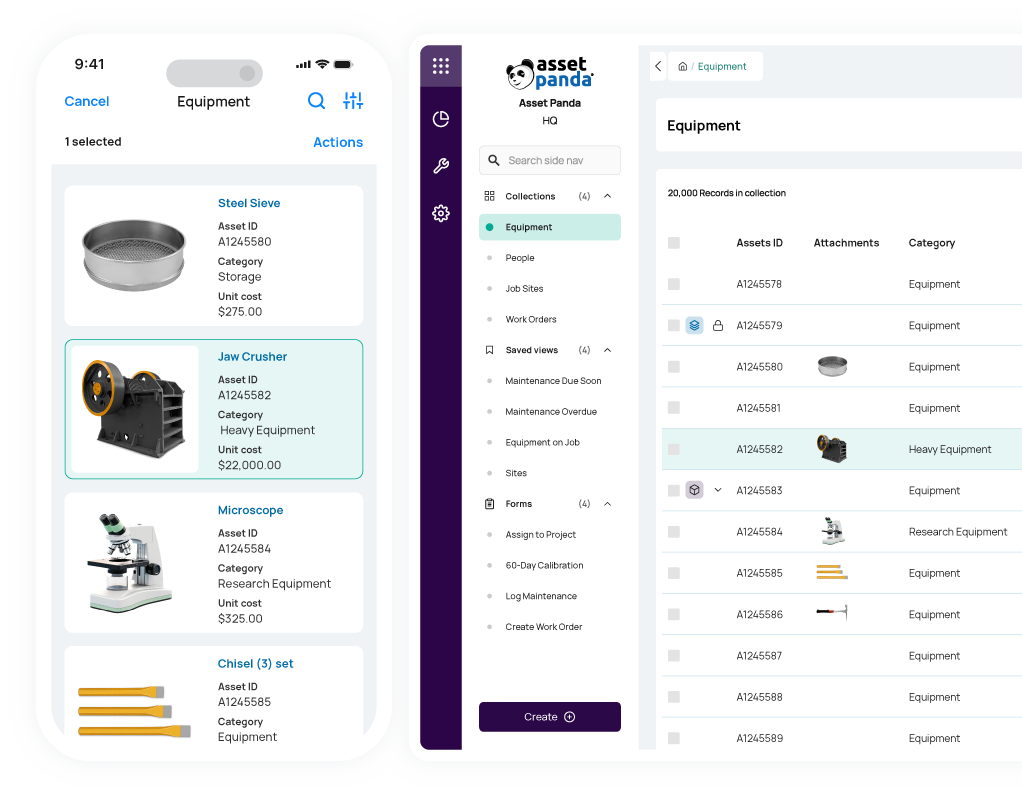

Track samples, lab instruments, and equipment in one cohesive place

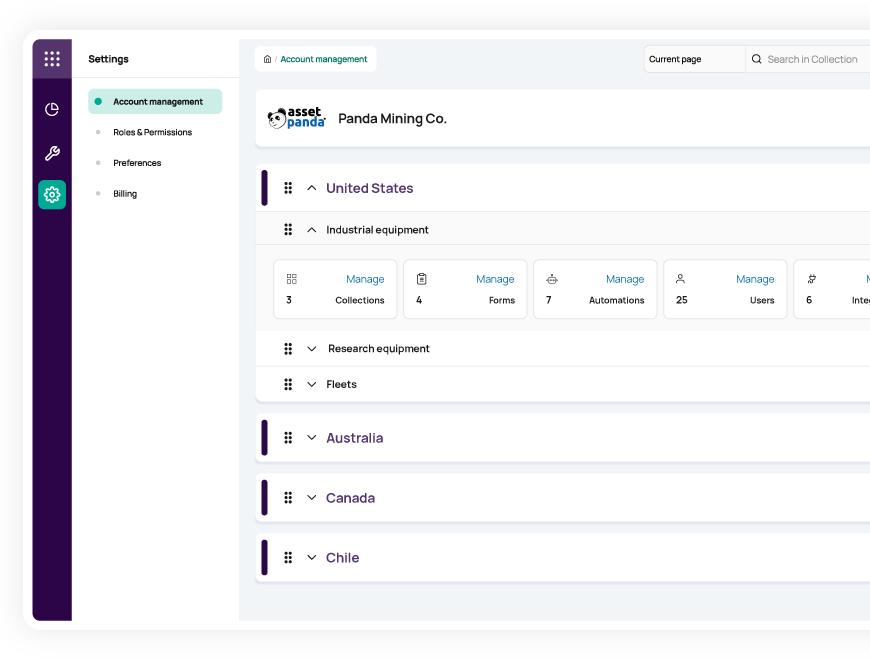

Create a single source of truth for all your samples and assets in our centralized mining LIMS. Keep track of various sample types, lab instruments, and equipment, and even create unique accounts for each of your locations in our multi-tenant platform. Plus, get your entire team on the same page with unlimited users and assign custom user permissions for increased security.

Standardize processes and recordkeeping

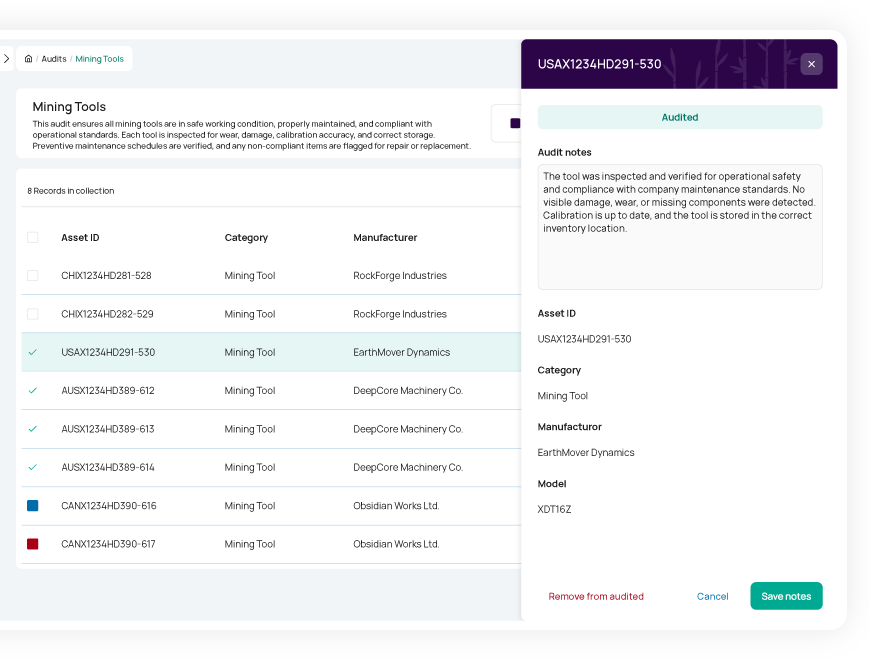

Enhance compliance with clear processes and audit trails

Customize and standardize your processes with our highly configurable mining LIMS. Ensure your workflows follow the correct sequence of events for safety and compliance, and further enforce your processes with required fields like signatures and photos.

Maintain clear audit trails including detailed sample records, full asset lifecycle histories, and audit and maintenance records in our materials LIMS. Attach user manuals to relevant asset records and even track individual employees’ training progress to further boost safety and efficiency.

Useful features for mining and materials

Related mining resources

Frequently asked questions

How can Asset Panda track heavy equipment maintenance based on mileage and service dates in remote areas?

Asset Panda supports heavy equipment maintenance by using custom fields for mileage and service dates along with automations. Technicians record Odometer or Hours-of-Use values through a form, and an automation can notify maintenance staff when the updated value meets or exceeds a defined threshold. A daily Scheduled Automation can also check for upcoming service dates and notify the team as the date approaches. This ensures maintenance is driven by both real usage and calendar requirements, which is essential for remote and high-duty equipment.

How does the mobile app's 'offline mode' support inventory audits and check-in/out processes in areas with no connectivity?

Asset Panda’s mobile app fully supports offline work, allowing field teams to conduct inventory audits and perform check-in, check-out, or transfer forms without connectivity. Users download the necessary data before going offline, then scan barcodes, update records, and submit forms locally on their device. All offline activity is stored securely and automatically syncs to the central system once the device regains connectivity, ensuring accurate asset tracking in remote or low-signal environments.

Can I use Asset Panda to enforce regulatory compliance and safety checks for critical equipment?

Yes. Asset Panda can support regulatory compliance by requiring safety inspection forms and using asset status controls. You can create a Safety Inspection form with required fields and signatures, and an automation can update the asset’s Status to “Available” only if the inspection passes. Checkout or usage forms can then be restricted to appear only when the asset is in an approved status. All inspections and updates are logged in the immutable Activity Stream and Form Submission History, providing verifiable documentation for compliance audits.

Can I connect Asset Panda to our GIS data using an API to track large geographic asset portfolios?

Yes. Asset Panda’s REST API can integrate with GIS platforms by pushing asset data—including GPS coordinates collected through mobile forms—into your mapping system. While Asset Panda does not provide native GIS visualization, the API enables you to synchronize location, status, and asset attributes with tools like ArcGIS, QGIS, or other mapping platforms. This allows mining, utilities, and field-operations teams to track and visualize geographically dispersed asset portfolios.

How can I track the costs associated with equipment repair and maintenance over time to inform replacement decisions?

Asset Panda supports replacement planning by allowing you to track repair and maintenance costs over the life of each asset. You can create a Repairs or Work Order collection with fields for labor, parts, and total cost, and link each record back to the asset. Saved Views and reports can then summarize an asset’s cumulative repair cost alongside its original cost or current book value (if depreciation is enabled), giving you clear financial insight into when replacement becomes more cost-effective than further repair.

How can Asset Panda help enforce mandatory pre-shift safety checks and regulatory maintenance for heavy equipment?

Yes. Asset Panda can support mandatory pre-shift safety checks by using custom inspection forms, automations, and asset status controls. You can require operators to complete a Pre-Shift Safety Check form—optionally including signature capture—and configure an automation to update the asset’s Status based on the inspection results. Checkout or “In Use” forms can then be restricted to appear only when the asset is in an approved status. If the safety check fails, the asset’s Status can automatically be set to “Out of Service,” preventing use until maintenance is completed. All inspections and updates are logged in the Activity Stream for compliance purposes.

Learn more from a solution specialist

Schedule a demo to find out how you can transform your workflows with Asset Panda Pro

Contact our team at (888) 928-6112