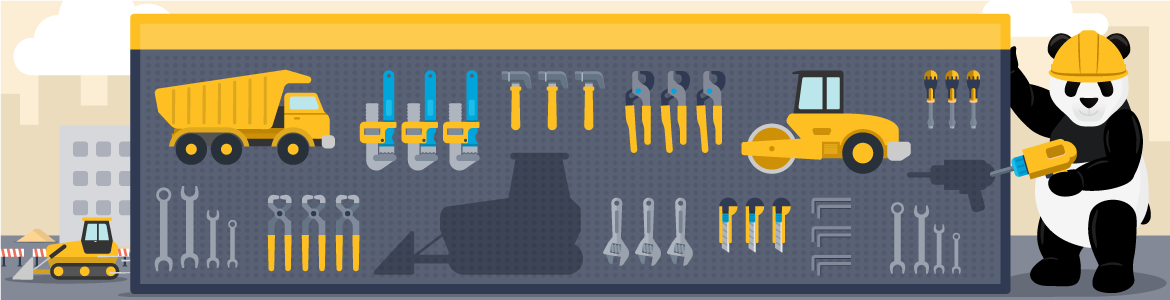

How to Make a Construction Tool Inventory System

Equipment theft on construction sites commands our attention because it translates to some significant dollar losses – an average of $400 million every year, according to the National Insurance Crime Bureau. We often don’t consider the tremendous loss resulting from construction tool theft.

The National Equipment Register reports that up to $1 billion in equipment, materials, and appliances are stolen from construction sites every year, and less than 25 percent is recovered. While a great many of these items are stolen by thieves in the dead of night, sadly, employee theft is a pervasive issue as well. Employees may be less likely to steal a trove of tools in a single incident and instead may pocket a tool here, a tool there, over months until the loss to the company is more substantial.

Why are construction tools such attractive targets for thieves? Two reasons: their value and the ease with which they may be stolen.

Construction tools that are stolen or lost through some other means can have far-reaching and negative effects on the projects in question. When a crew arrives on site to discover that critical tools are missing, completion delays are likely to occur, resulting in crews standing idle – and, ultimately, unhappy clients. The construction company then has to rush-order replacement tools or find available inventory elsewhere, on a different project site, or in the warehouse.

Construction companies must have a construction tool inventory system – no two ways about it. Investing in a construction tool inventory system can reduce theft and loss, save construction companies time and money, maintain client satisfaction, and maintain efficiency.

How Should a Construction Company Build a Tool Inventory System?

Take a Job Site by Job Site Approach

Construction companies manage multiple projects at any given time, so the most effective way to begin your tool inventory system is to require each of your job sites (and each of your central locations) to conduct an inventory of their respective construction tools.

Apply Barcode Labels to Your Equipment

As each job site performs its tool inventory, construction companies should apply barcode labels and create a record to relate the barcode ID to the tool. You may wish to create barcodes yourself or order barcode labels that come in a variety of materials designed to withstand harsh conditions and other wear and tear.

Import Your Asset Data into an Inventory Tracking System

Depending on the construction tool inventory system you use, it can be very easy to import Excel spreadsheets into your new system. You can include data like:

- The tool purchase date

- Costs of assets and equipment

- Barcode IDs

- The condition of a construction tool

Categorize Your Tools

Categorizing your construction tools provides a faster way to track items within the construction tool inventory system.

Consider creating groups of tools within your system that you commonly use together. Kitting, or the grouping of tools into a set used routinely for multiple projects, is an invaluable feature offered by construction tool inventory systems. It can save companies considerable time.

Your work crews may perform the same task for multiple clients. These tasks often use a specific set of tools to accomplish. Instead of trying to gather tools piecemeal, with a construction tool inventory system, you can quickly assign groups of tools to a job, vehicle, and employee and get them on their way to a job site quickly.

Creating toolsets allows you and your technicians to have items on hand in case something unexpected happens without needing to return to the office to grab something you should have brought along. It’ll also save on the amount of time everyone spends locating and putting away tools.

Add Your Users to The System

The construction tool inventory system should be accessible to every stakeholder involved in the lifecycle of your construction tools. Aim to make the system visible organization-wide so that an individual at one site can view available inventory at another and make requests if necessary. Of course, users will have different permissions settings; you’ll want to establish who may make modifications inside the system and who may access the system in read-only mode.

Establish Policies and Procedures

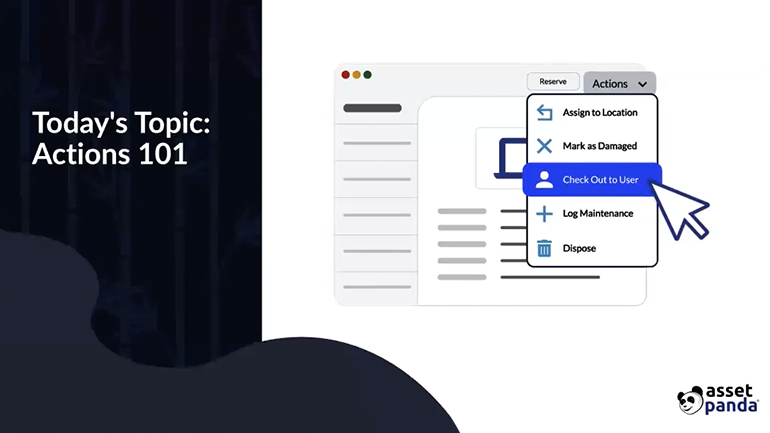

The success of your construction tool inventory system will depend mainly upon the policies and procedures you build around it and how well you enforce them. You should consider implementing procedures like tool check-in and check-out, so stakeholders have complete visibility into where tools should be located and when they should return to your inventory.

You could also assign one individual from each crew to monitor tools and their safe return upon the project's conclusion. You may also wish to set up custom reminders for those who are approaching their assigned tool return dates to ensure you have enough time to inspect and maintain tools, so they're ready for another job.

Consider Tracking Tool Usage

Which items are receiving the most wear and tear? Which tools aren’t getting much use? This information can be invaluable for budgeting and project planning.

Track Repair and Maintenance Histories

Do you have tools that are running into the same issue repeatedly? Are you paying for the same repairs over and over again? In a busy construction business, these realities may cause headaches on job sites that might not get fully communicated to management. A construction tool inventory system helps administrators uncover such waste and determine when it may be time to replace tools.

Use a Mobile and Cloud-based Solution

When you’re determining the best construction tool inventory system for your company, consider the ease and convenience that a mobile app can provide your crew members. A mobile app – particularly one with a built-in barcode scanner – allows employees to access tool tracking data 24 hours a day, seven days a week from wherever they happen to be. When the app syncs with the cloud, construction companies have the assurance of knowing that their data is up to date so they can make decisions confidently.

The Benefits of Using Tool Inventory Software

In addition to simply knowing the location of your tools at any given time, a construction tool inventory system provides you with a place for storing all relevant information attached to the lifecycle of your construction tools – for example:

- Lease or purchase information,

- certifications,

- part replacements,

- service information,

- their complete maintenance history,

- insurance information,

- warranty information, and much more.

A cloud-based tool inventory software system like Asset Panda isn’t just good for tracking your inventory. It’s also a great way to assign tools to each job site. Coupling client jobs with inventory tracking is a great way to kit your employees with everything they’ll need to get a job done.

Having a system in place will save your company hours of work and will allow you to take on more clients. Assigning jobs in this way makes your workflow more efficient and provides crew members with a lot of information before they even arrive at the work site. They’ll have an idea of what to expect and won’t be trying to figure it out and work on it at the same time.

Being able to track all of your equipment and tools from a centralized location will make it easier for you to see when you’re about to run out of specific toolsets. Tool inventory software helps you allocate client jobs according to who and what is available. If you know ahead of time that you won’t be able to tackle four of the same type of job, then you can schedule other tasks to ensure your equipment isn’t double booked.

Tool inventory control is vital for construction companies attempting to rein in wasteful spending. By providing transparency, construction tool inventory systems eliminate project delays and save staff members the time and hassle required to track down available tools. If they don’t know the tools they have or where they’re located, construction companies may spend thousands on items they don’t need.

Asset Panda's Tool Inventory Tracking System

Asset Panda enables construction companies to add as many users as they’d like at no additional cost. It also includes a full suite of customizable features, so they can track and manage their assets any way they want. With a built-in scanner, Asset Panda’s mobile app requires only the smartphones that crew members already carry and provides them 24/7, real-time access to the complete lifecycle of their tools and other fixed assets.

Our software offers several integrations, so introducing Asset Panda into your existing workflow is easy. And our user interface is streamlined and intuitive, so staff won’t need to complete extensive training to get up to speed.

If you’re ready to get your tool inventory under control and stop losing thousands to theft, loss, and mismanagement of your construction tools, give Asset Panda's tool inventory management software a try with a free 14-day trial (no credit card required)! You’ll receive full access to user guides, video tutorials, free mobile apps, and call-in and live chat support from our friendly Asset Panda support team.

Related News & Press

Learn more from an Asset Panda expert

Get a FREE consultation with an asset tracking expert to find out how you can transform your asset tracking.

Contact our Sales Team at (888) 928-6112