Inventory Management Examples: Big Mistakes Made by Huge Brands and How To Avoid Them

Blog

Table of Contents

Take Control of Your Assets

A personalized demo is just one click away.

Inventory management, the process of tracking and controlling the flow of goods, is a crucial component of any organization’s supply chain. Inventory management examples include monitoring the flow of inventory from acquisition to sale, storing inventory in warehouses, and ensuring it is delivered without waste or loss. When these tasks are performed incorrectly, they can lead to short-term financial damage, a fall in stock prices, bankruptcy, or even company closure.

From small startups to international conglomerates, inventory management can present both immediate and long-term challenges. High-profile, well-known, and well-loved brands are not exempt from the difficulties of inventory control, and many retailers can learn valuable lessons from their mistakes. Here are four memorable examples of inventory management errors that cost big brands big time—and what they might do in order to fix them.

1. Target’s Overly Optimistic Overstock

In June 2025, Target stores across America dropped the prices of more than 10,000 types of items to just $5. This fire sale was a desperate attempt to jostle the big box store’s sluggish inventory movement. After a post-pandemic boom, Target’s sales stagnated, then sank over the following four years.

What happened? Target failed to predict shifting consumer behaviors and, in turn, how much inventory it needed to make available in stores. Since 2022, the big box store has struggled with trimming down excess inventory to more manageable levels, slashing prices to entice customers and leaving shareholders to take the financial hit as stocks plummeted. The problem only ballooned in 2025 as Target made drastic changes to company policies and faced increasing consumer uncertainty over US tariffs.

The company is stuck in a vicious cycle. Low prices on excess inventory mean it earns less, and when it attempts to save money in other ways, like cutting staff, it pays for it in messy stores. It presents a stark inventory management example of how poor management can result in a downward spiral.

2. Funko Pop Takes Out The Trash

In the 2010s, Funko Pop couldn’t keep enough of their big-eyed figurines of pop culture icons, spanning from Mickey Mouse to Michael Jackson, on the shelves. But in 2023, the company got some bad press when it admitted it retained $250 million in excess inventory from the previous year. Citing limited warehouse storage capacity and waning demand, the company dumped nearly $300 million of the formerly in-demand toys straight into landfills.

Funko Pop is a dramatic example of how liquidating stock can be costly for a company—both financially and in regards to reputation. However, there were signs the company could have paid attention to earlier. In its 2022 Q4 earnings call, it told investors that it was still holding on to 48% more inventory than it had the previous year. If Funko Pop had kept a better eye on quarter-over-quarter inventory using a centralized management software, it might have avoided such an extreme outcome.

3. Gap Inc.’s Sales And Inventory Gap

American clothing retailer Gap Inc., which also owns Athleta, Banana Republic, and Old Navy, is a fixture of every mall. But the multinational retailer found itself in hot water in 2022 when the company found itself stuck with $3.04 billion of excess product, up 12% from the previous fall. Big discounts and slashed prices helped lighten the load, but still hurt the brand overall. By 2024, the inventory issue had come back to haunt Gap Inc. again. The company reported a 3.6% inventory increase for 2024, leading to more even markdowns and lower overall revenue.

Gap Inc.’s ongoing struggles indicate that the company’s long-term strategies are no longer successful in a post-pandemic world–the way people live, work, and shop has changed. The problems Gap faces are not reflected in its closest competitors, like H&M and Zara. The company would do well to explore different strategies that could lead to less overstocking and even model its competitors’ examples of inventory management.

4. Nike’s Bad Bet On Sportswear Demand

Another formerly strong clothing brand that struggled to pivot after the pandemic was sportswear royalty Nike. Though consumers increased their athleisure wardrobes during the months of quarantine, the brand has yet to convert shifting consumer attitudes into increased sales. In March 2025, Nike forecast that sales would continue to decline at a rate in the mid-teens all year. “We are going to continue to be liquidating inventory, and we expect that that’s going to take us several quarters to work through,” Nike’s Chief Financial Officer Matthew Friend told investors. What was the problem? After the global pandemic wreaked havoc on global supply chains, Nike attempted to stock up to avoid low supply, and instead ended up with more than it needed.

For Nike, liquidating inventory has meant deep discounts on products, cutting gross margins by 400–500 basis points. But the company told investors that this is all to clear shelf space for newer, more modern products. Nike is also looking toward China, where sales are down even more than in the US. By skillfully managing its supply chain using an updated inventory management software, the retail brand can revitalize itself by providing new products that resonate with modern customers and making sure that those products are transferred efficiently to retailers. It can also use that software to make more effective forecasts for consumer demand and avoid overstocking in the future.

5. Sidestepping Inventory Disaster With Asset Panda

The four examples of inventory management errors in this article each show different types of inventory disaster, but they can all be boiled down to one solution: carefully tracking your company’s stock on a regular basis to avoid an unexpected glut of excess inventory piling up. Even the biggest names are not immune from the importance of day-to-day inventory management. But this age-old problem requires a modern solution: software that works for a company’s specific needs.

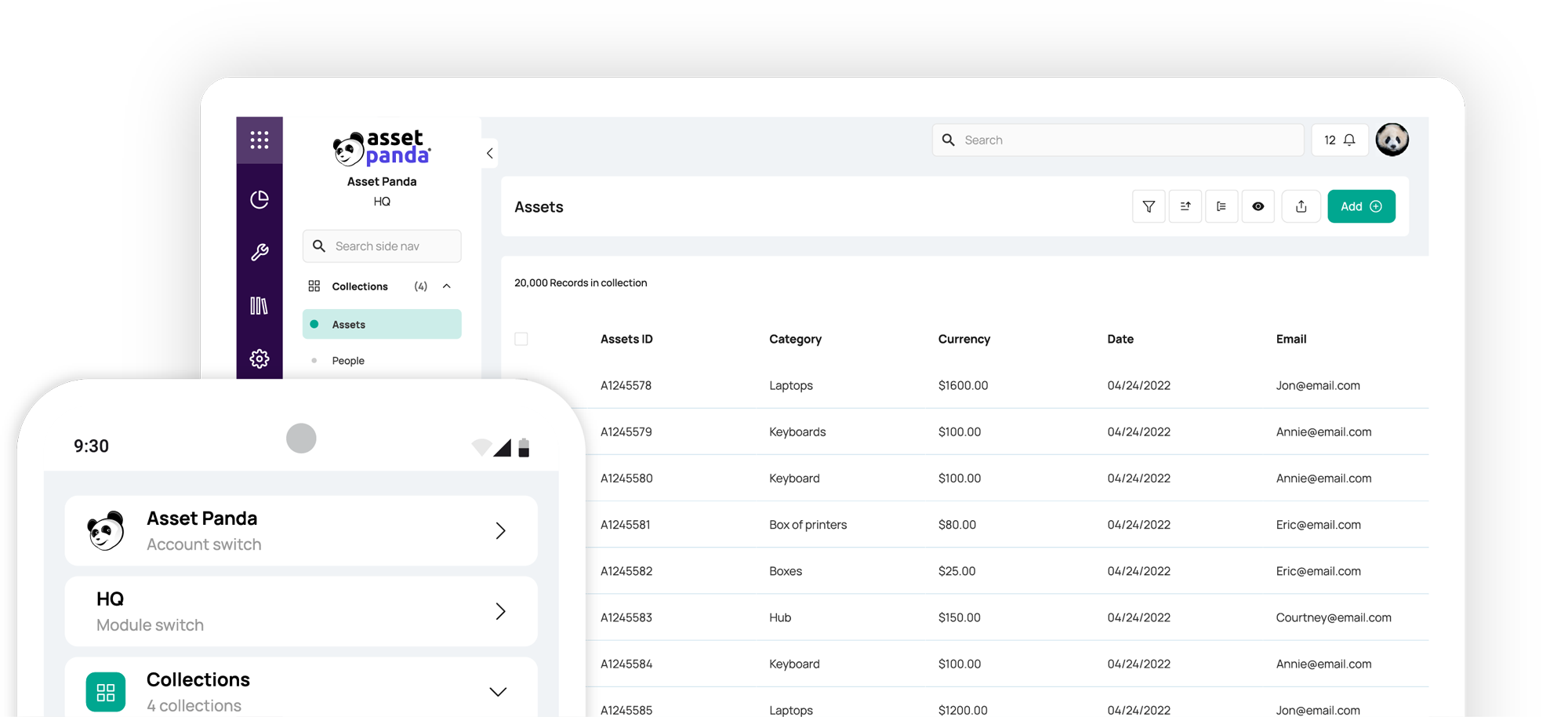

Avoid replicating these unfortunate inventory management examples with a comprehensive and easy-to-use solution like Asset Panda. Asset Panda’s customizable software allows your organization to track both assets and inventory in one cohesive place. Whether you’re managing inventory for a standalone shop or an organization with offices all over the world, Asset Panda’s robust solution can be tailored for your needs with features like mobile access, barcode scanning, and automatic reports.

Find out why thousands of companies entrust their inventory management to Asset Panda when you request your customized demo today.

Take Control of Your Assets

A personalized demo is just one click away.

Related News & Press

Learn more from a solution specialist

Schedule a demo to find out how you can transform your workflows with Asset Panda Pro

Contact our team at (888) 928-6112