Equipment Management Software

Stop searching, start working

Track and manage your equipment in real time, create work orders, and more with our easy-to-use software.

(No Credit Card Required)

AI Enhanced

Improve your efficiency with the power of Asset Panda Intelligence.

Streamlined Work Orders

Easily create and assign work orders for increased efficiency.

Customizable Workflows

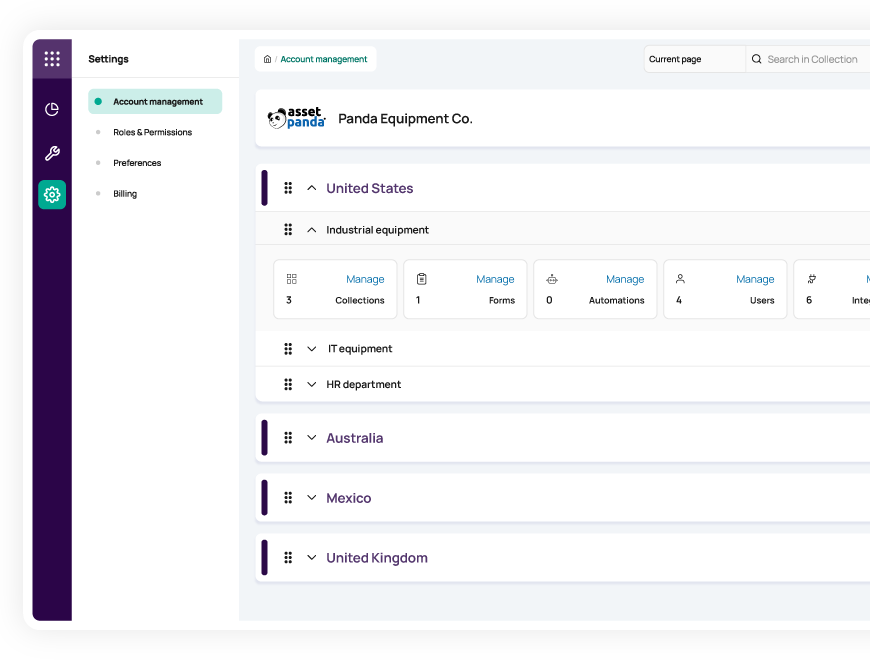

Configure the platform to match the way you already work.

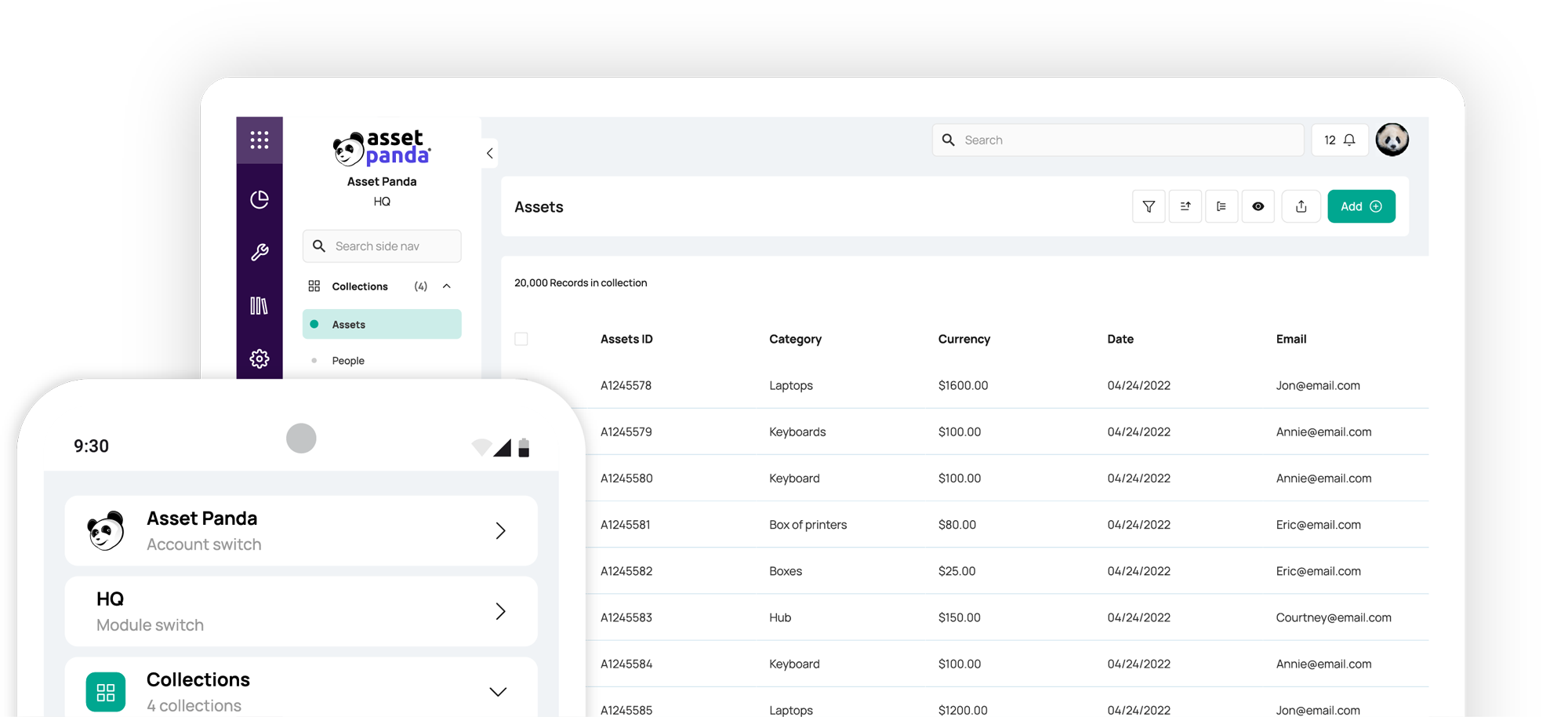

Get real-time visibility into your equipment

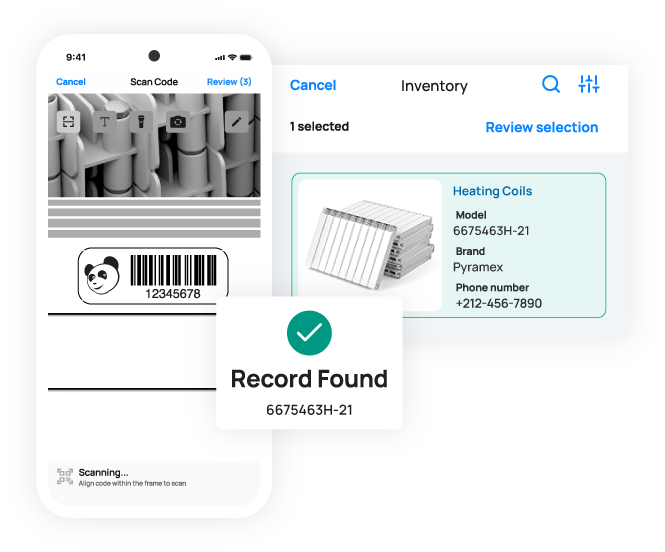

Easily track and manage your equipment on the web or on mobile

Monitor the status, location, and condition of your assets with our real-time equipment management software. Plus, empower your team to check out equipment or request repairs from anywhere with our mobile app with available offline mode. Generate and print your own unique barcodes or QR codes and scan them directly on your mobile device – no third-party scanners required.

Stay ahead of equipment maintenance

Create and assign work orders in one easy-to-use system

Streamline preventive maintenance and work orders with our comprehensive equipment maintenance software.

- Accurately forecast and schedule upcoming maintenance tasks

- Create custom work orders and automatically assign them to available team members

- Increase productivity and reduce potential equipment downtime

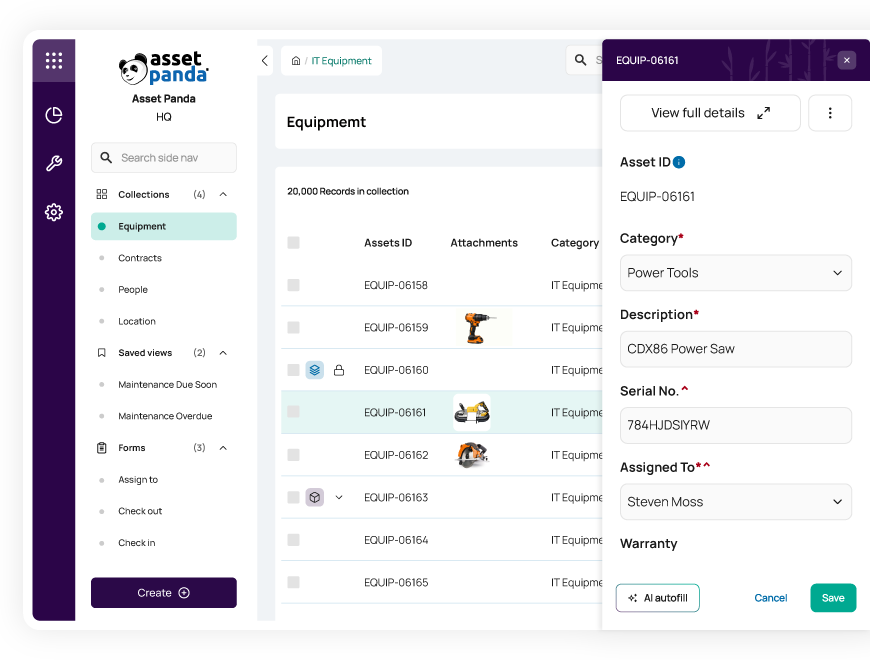

Track the full lifecycle of your equipment

Optimize equipment utilization and reduce costs

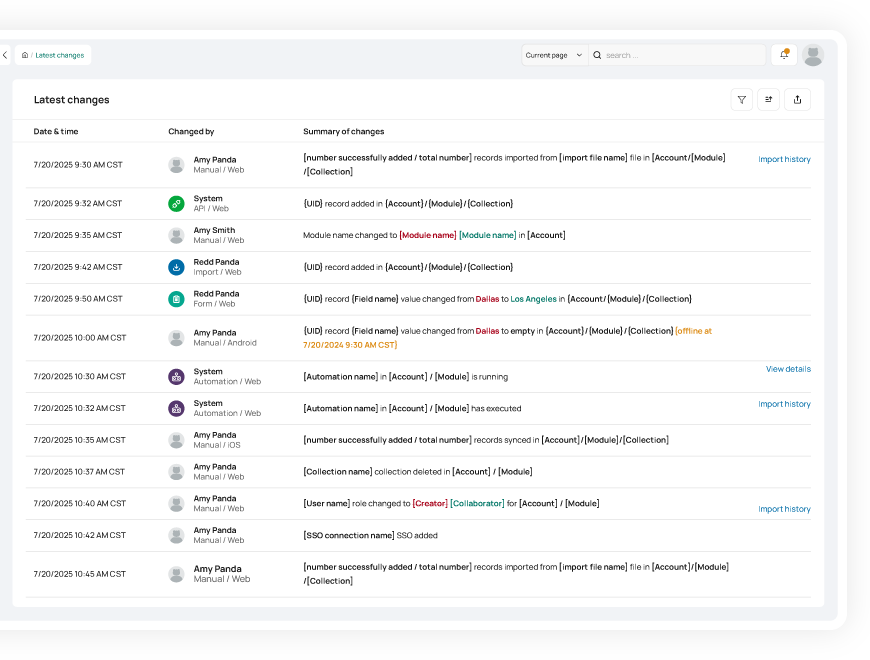

Access the entire lifecycle history of your equipment from acquisition to disposal with our robust equipment maintenance software. Track every update in our detailed asset records, including assignment and repair history, recommended maintenance dates, and current depreciated value. By giving you full insight into an item’s current condition and value, our equipment management software helps you optimize asset utilization and improve cost savings.

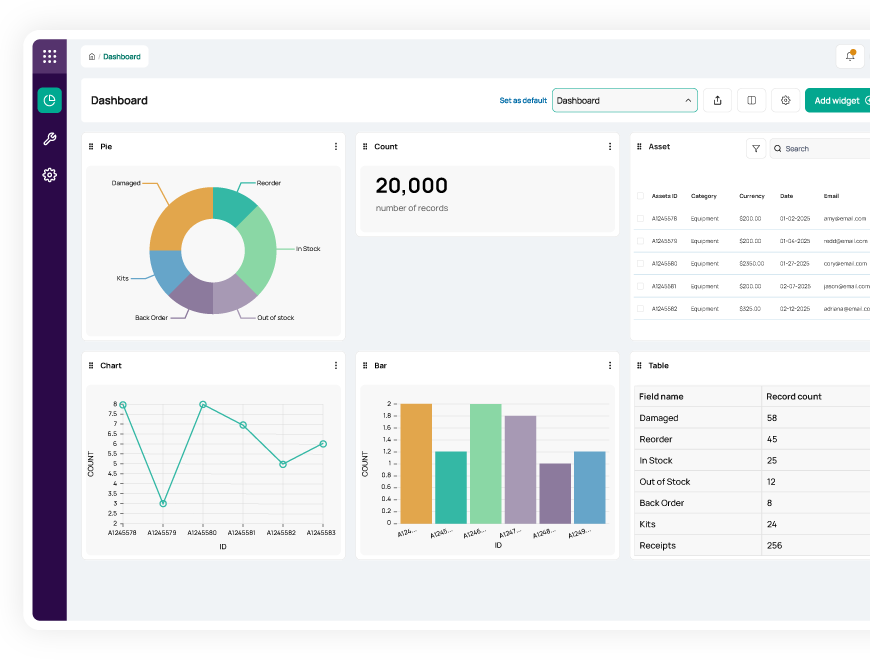

Make better data-driven decisions

Increase productivity and uptime with custom alerts and reports

Gain the actionable insights you need to keep your team productive with our equipment management software.

- Generate reports with virtually unlimited filters and set automated reporting schedules

- Create custom notifications to alert you of work order requests, status changes, and more

- Optimize asset utilization and forecast upcoming purchasing needs

Useful features for equipment management

The Budd Group gives employees easy access to vehicle info

“Depending on their level of access, employees and managers can find everything they need about a vehicle in one place, from training to a location to a vehicle inspection history and maintenance needs.”

Dale Christensen

Operations Manager

RISE™Robotics Uses Asset Panda as Their Single Source of Truth

"Almost every company that I could see myself working for in the future would benefit from something like Asset Panda if they don't already have it."

Tom Rufo

Lab Manager

Electrical Construction Company Saves Several Hours of Work per Day with Asset Panda

"As a team, we're constantly putting our heads together and saying, 'What are we doing now and how can we do it better? The flexibility of what we can do in Asset Panda makes it attainable for us to push the software even further."

Implementation Specialist

Related equipment resources

Learn more from an Asset Panda expert

Get a FREE consultation with an asset tracking expert to find out how you can transform your asset tracking.

Contact our Sales Team at (888) 928-6112