How MP2 Preventative Maintenance Software Helps Your Business

Blog

Take Control of Your Assets

A personalized demo is just one click away.

Making sure your equipment and machines are working as expected is essential to helping your business run as smoothly as possible. By taking advantage of an mp2 preventative maintenance software ("mp2" stands for computerized maintenance management system), your company can keep track of your equipment maintenance and simplify work orders.

While equipment maintenance can seem frustrating and takes a lot of time, the alternative is something you'll want to avoid at all costs. When you don't take the time to repair your equipment, your facility can run into several problems that will complicate your work day. You might be lucky and only experience a slight problem, like a machine working slowly or less efficiently. Or you might be unlucky and have a machine completely fail.

Keeping up with your equipment maintenance needs is a safety measure that your organization should take seriously. Along with helping your workers stay safe, there are several other benefits of using an mp2 preventative maintenance software.

The Benefits of MP2 Maintenance Software

Lower Equipment Costs

Equipment can get expensive, especially when replacing machines that no longer work. However, when you effectively maintain your equipment, you can extend its lifespan by several years, potentially saving you thousands of dollars. When you can make your assets last longer, you increase not only their lifespan but also increase their ROI. In almost every circumstance, paying for repairs is less costly than completely replacing a machine. And regular maintenance on your equipment will also reduce the likelihood that you'll need to order emergency repairs in the case of a catastrophic failure.

Streamline Workflow with MP2 Preventative Maintenance Software

When your equipment stops working, it can seriously mess with your work day. However, an mp2 preventative maintenance software can help you identify the best times to schedule your equipment for repairs. The right software will help you determine when your employees are more likely to use your machinery and when your equipment is not in use. Having your machines maintained during work downtimes will help your team continue completing work during busy times without worrying about interruptions.

Schedule Work Tasks Effectively

Knowing when your equipment is going in for maintenance will also help you schedule work tasks during appropriate times. Without a software plan, you might accidentally schedule your team to work on an important order when a specific machine is undergoing maintenance. Using good preventative maintenance software will help you avoid double booking and get back to work with less hassle.

Get Relevant Equipment Maintenance Data Over Time

Keeping maintenance records in your software can help you in many ways. You'll see which assets are performing well and which aren't earning their keep. When a piece of equipment starts to show signs of wear, you'll be able to see what repairs it has undergone in the past year or so. If a specific machine keeps failing, maybe it's time to replace it instead of pouring more money into repairs. By using this data, you can make better decisions on what to do with your equipment.

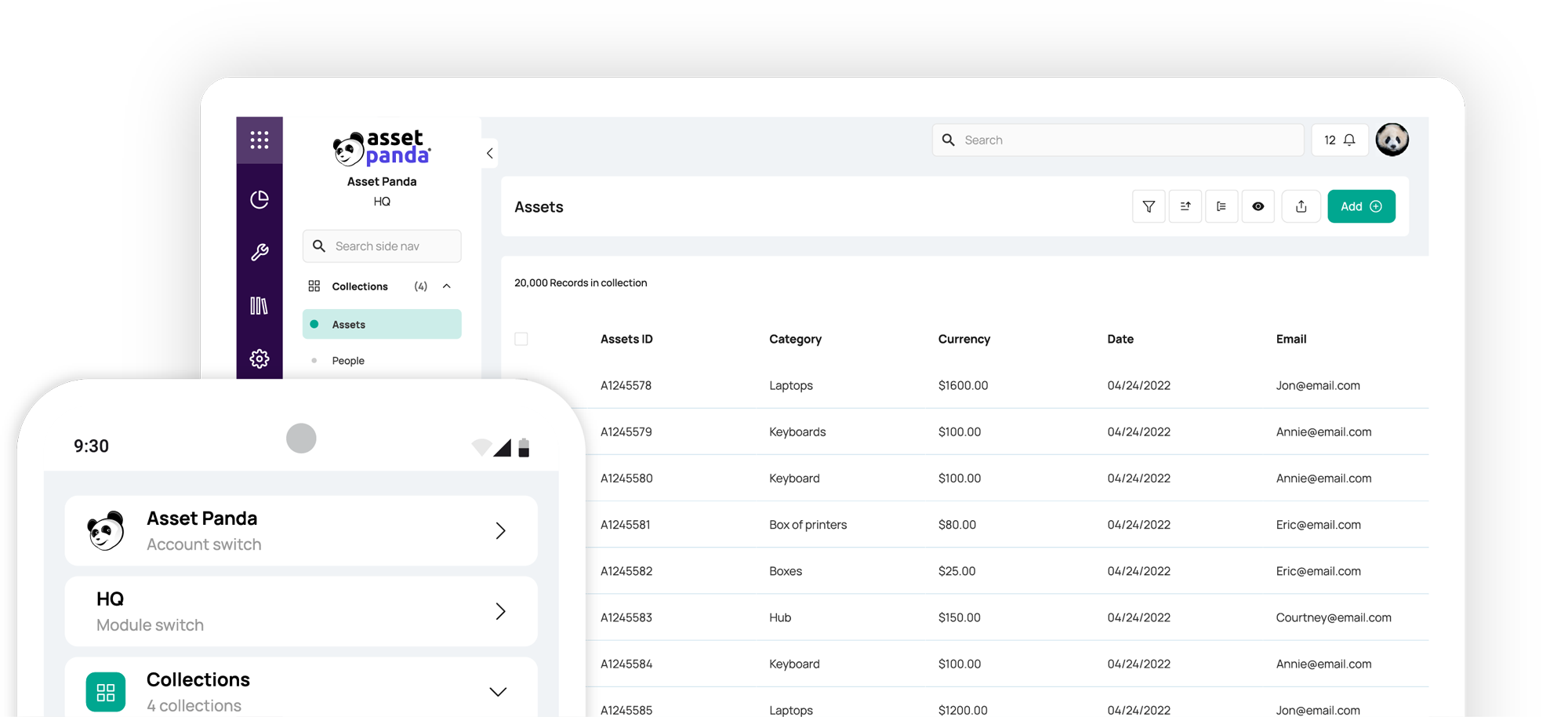

Asset Panda's MP2 Maintenance Software

Asset Panda's cloud-based software makes it easy for you to schedule preventative maintenance needs to benefit your business.

Give Asset Panda's CMMS software a try with a free 7-day trial (no credit card required)! You’ll receive full access to user guides, video tutorials, free mobile apps, and call-in and live chat support from our fantastic Asset Panda support team.

Take Control of Your Assets

A personalized demo is just one click away.

[addtoany]

Related News & Press

Learn more from a solution specialist

Schedule a demo to find out how you can transform your workflows with Asset Panda Pro

Contact our team at (888) 928-6112