Customizable asset management software

Meet Asset Panda, the highly configurable platform that matches the way you work. Our agnostic and centralized asset management software allows you to track various asset types in one convenient place. Easily customize the platform to echo your team’s current naming conventions and workflows for fast time to value.

Get full visibility into your asset inventory

Never lose track of an item again with our real-time asset management software

Boost productivity and make more informed decisions with full transparency into the state of your assets. Access the real-time status of any asset along with its full lifecycle history, including its current depreciated value, repair and assignment history, warranty information, and more.

Between robust asset records and custom reports, our asset tracking software provides the accurate data you need to proactively manage upcoming maintenance dates, better forecast future purchasing needs, and optimize asset utilization, ultimately reducing potential downtime.

Unify and secure your tech stack

Create a single source of truth for your data in our secure asset tracking software with 18+ integrations

From ticketing systems to active directories, our asset management software integrates with 18+ popular applications to help you streamline workflows and break down data silos. Automatically sync important asset and workflow information directly to Asset Panda to maintain accurate data, avoid duplicate work, and save time.

Beyond unifying your asset management data, our cloud-based asset tracking software also protects your data with SOC 2 Type II certification and TLS 1.2 encryption.

Update asset records from anywhere

Conduct workflows on the go using our mobile asset tracking software with built-in barcode technology

Whether you have team members working remotely or out in the field, Asset Panda’s mobile app empowers them to access and update asset information from anywhere. From requesting repairs to conducting audits, our mobile app makes it easy for your team to stay on track, even on the go.

Plus, Asset Panda’s built-in barcode technology can save your team even more time by looking up items with a single scan. Seamlessly create and print your own barcode labels and scan them directly on your mobile device (no third-party scanners required!). Barcode scanning not only helps your team reduce manual effort but also improves data accuracy – a win-win.

Get your entire team on the same page

Achieve high user adoption with unlimited users and customizable permissions

Easily assign assets to employees and uphold your workflows with unlimited users and customizable user permissions. Grant the right access to the right people to enhance data integrity and increase accountability. With an intuitive interface and comprehensive onboarding for all your users, you’ll realize fast time to value and high user adoption.

Boost accountability with reliable asset tracking

Track the status, location, and condition of your assets for increased accountability and efficiency

Always know where your assets are, who they’re assigned to, and what condition they’re in with our real-time asset tracking software. Whether you need to assign IT devices to employees or send equipment out for repair, seamlessly update the status of your assets to ensure your data stays up to date. Plus, easily conduct routine audits to confirm the state of your asset inventory and prevent loss or damage.

Unlimited Users

Get your entire team on the same page and set custom user permissions.

Fast Time to Value

Achieve high user adoption and ROI with our intuitive interface.

Customizable Workflows

Configure the platform to match the way you already work.

Explore all of our features

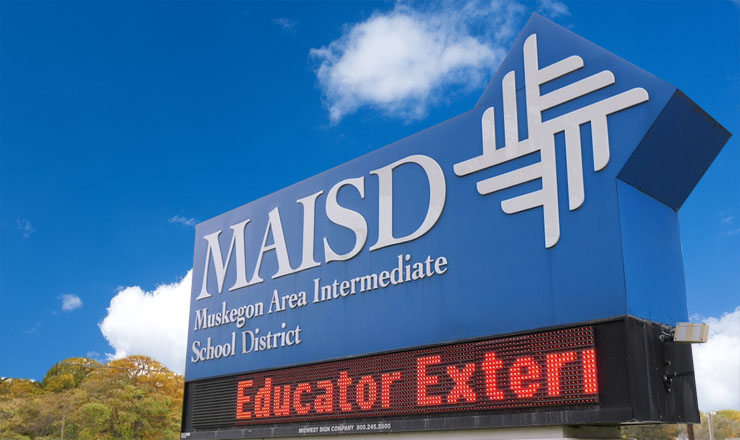

Muskegon School District Saves 100 Hours per Year

“Switching over to Asset Panda saved us thousands of dollars over what we were doing before. It's streamlined our process and made it really easy for our end users to know where our assets are.”

Tim Brown

Director of Technology Services

RISE™Robotics Uses Asset Panda as Their Single Source of Truth

"Almost every company that I could see myself working for in the future would benefit from something like Asset Panda if they don't already have it."

Tom Rufo

Lab Manager

On-Wing Services Team Saves Over 4,000 Hours per Year

“With its flexibility and all of the ways we can use this tool, Asset Panda affects every aspect of our operations. It's the foundation of the way we're doing a lot of things now."

Tony Ross

On-Wing Services Quality Director

Related asset resources

Frequently asked questions

What is an asset?

An asset is something a business or organization uses as part of its operations. Common assets include:

Asset Panda's pricing is based on how many assets you'd like to track, and our configurable system can be set up to track just about anything.

What if I don't know how many assets I have?

Our experts will be happy to work with you to determine what asset count will work best for you. If you find that you need to track more assets down the road you can upgrade your account at any time.

Visit our pricing page to learn more about our packages (based on asset quantity) and to get a quote.

Do I need to buy a barcode scanner?

Nope! Forget about buying expensive barcode scanning hardware.

One of the biggest advantages of the Asset Panda system is the integrated barcode scanning function included in the mobile app. Any user with a mobile device can quickly search, update, and maintain asset records to improve the accuracy of your data.

Do I need to buy barcode labels?

If you want to print your own barcodes, you can easily do so with the barcode generator built into Asset Panda's web app.

If you need barcodes that can stand up to heat, moisture, chemicals, or other environmental hazards, Asset Panda has partnered with a team of experts who can help you out.

How does Asset Panda help clients reduce costs and increase profits?

By providing a central system of record for assets, Asset Panda helps clients save money by reducing property taxes, property insurance, Federal/State taxes.

Asset Panda also helps our clients reduce asset losses due to misplacement, theft and mis-allocation and enables clients to avoid double-purchases and early equipment breakdowns with better tracking and consistent maintenance.

Learn more from an Asset Panda expert

Get a FREE consultation with an asset tracking expert to find out how you can transform your asset tracking.

Contact our Sales Team at (888) 928-6112