Visibility in Action: How to Improve Inventory Management

Blog

Table of Contents

Take Control of Your Assets

A personalized demo is just one click away.

Improving inventory management is a critical goal for organizations across industries. Effective inventory control ensures that businesses have the right stock at the right time, preventing costly shortages or wasteful overstocks. In this article, we’ll explore the importance of effective inventory tracking and how to improve inventory management in your organization with practical strategies.

The Importance of Inventory Management

Inventory is often one of the largest assets on a company’s balance sheet, and managing it well is vital to operational and financial performance. Poor inventory management can lead to lost sales, production delays, or unnecessary expenses. Globally, inventory distortion (from stockouts, shrinkage, and overstock) costs businesses an estimated $1.6 trillion annually, underscoring the high stakes of efficient inventory control.

Here are a few examples of how inventory management benefits different industries.

- Manufacturing: In manufacturing, inventory management is essential for keeping production lines running smoothly. Missing raw materials or spare parts can halt production, while excess inventory ties up working capital. Most businesses have 25–30% of their working capital tied up in inventory, so optimizing stock levels can free significant funds. Effective practices like just-in-time inventory help manufacturers reduce waste and storage costs without causing shortages.

- Healthcare: Hospitals and healthcare providers rely on meticulous inventory management for medical supplies and equipment. Efficient inventory management in healthcare ensures that medications, surgical instruments, and personal protective equipment are available when needed and not lost or expired due to oversight. This not only controls costs but also improves patient care by preventing delays or errors.

- Information Technology (IT): In IT and data centers, inventory management often refers to tracking hardware devices (like servers, laptops, and networking gear) as well as software licenses. For IT departments, losing track of assets can result in wasted budget, security risks, and compliance issues.

Strong inventory management helps IT teams know exactly what assets they have, where they are, and when maintenance or upgrades are due. For instance, with the rise of remote work, companies must track laptops and equipment outside the office; one survey found a large percentage of employees fail to return company-issued devices, highlighting the need for better IT asset tracking. Proper processes ensure valuable tech equipment isn’t misplaced and that software licenses are utilized efficiently, ultimately saving money and reducing downtime.

Effective inventory management benefits every industry by boosting efficiency, reducing costs, and improving service levels. It prevents situations like stockouts that can erode customer trust, and curbs overstock and waste.

Read More: What is Inventory Management?

7 Actionable Tips to Streamline Your Inventory Management

To address these challenges, here are actionable tips on how to improve inventory management and streamline your operations. These strategies are applicable to mid-to-enterprise organizations and can be tailored to industries from manufacturing to healthcare and IT. Implementing even a few of these tips can significantly improve inventory management efficiency and accuracy:

1. Adopt a Modern Inventory Management System

Ditch spreadsheets and manual tracking in favor of dedicated inventory management software. A cloud-based system provides a single source of truth for all inventory data, with real-time updates accessible to your entire team. This is especially valuable for enterprise organizations with multiple warehouses or locations.

Modern systems (often accessible via web and mobile apps) enable you to monitor stock levels in real time, update records instantly when items are received or issued, and maintain accurate counts across all sites. By investing in a robust system, companies can reduce errors, prevent stock discrepancies, and gain visibility into inventory status at any moment.

2. Automate Tracking with Barcodes, RFID, or IoT

Automation technology greatly improves inventory management by increasing accuracy and speed. Replacing manual data entry with barcode or RFID scanning can eliminate transcription errors and provide instant updates. In fact, using barcode tracking has been shown to reduce human error in inventory processes by over 40% in some cases.

Consider tagging all items or assets with barcodes or RFID chips and equipping staff with mobile scanners or smartphone apps to record movements. Many warehouses are also embracing IoT sensors and real-time location systems to continuously monitor inventory. By automating inventory tracking, your organization can maintain far more accurate stock data, react faster to changes, and significantly cut the labor time spent on audits and searches.

3. Perform Regular Audits and Cycle Counts

Even with good systems in place, it’s important to routinely verify that recorded inventory matches the physical stock. Schedule regular audits or cycle counts (aka counting a subset of inventory on a rotating basis). This practice helps catch discrepancies early and keeps accuracy high. For example, many companies do daily or weekly cycle counts on high-value or fast-moving items (an “A” category in ABC analysis) to ensure records stay correct.

Regular auditing not only prevents small errors from snowballing into big problems but also reinforces accountability among staff. It’s easier to improve inventory management when you have reliable data, and frequent cycle counts are a proven way to maintain data integrity without the disruption of full annual stocktakes.

4. Optimize Stock Levels with Forecasting and Reorder Points

Striking the right balance between too much stock and too little is a core goal of inventory management. Leverage data to forecast demand and set optimal reorder points. Modern inventory systems often include forecasting tools or integrate with analytics platforms to assist with this.

You can also employ techniques like safety stock (a small buffer of critical items) to protect against unexpected spikes in demand or supplier delays, but calibrate these levels carefully to avoid overstocking. Optimizing in this way has tangible benefits: companies with refined inventory optimization practices can reduce inventory costs by 10% or more through better balance. By continuously refining your predictions and adjusting reorder thresholds, you’ll keep inventory lean yet capable of meeting customer or production needs.

5. Use ABC Analysis to Prioritize Management Efforts

Not all inventory items are equally important. ABC analysis is a method that segments inventory into three categories: A (high-value or high-impact items, typically ~20% of items accounting for ~80% of value), B (moderate value items), and C (low value, many items that together account for a small portion of value). Focus your tightest controls and most frequent reviews on the “A” items – these might be your most expensive raw materials, or critical components, or best-selling products. Ensure accurate counts and secure storage for A items, since discrepancies with those are most costly. “B” items get moderate attention, and “C” items can have simpler controls.

For example, a hospital might classify life-saving drugs and expensive implants as A (with very strict tracking), routine medical supplies as B, and inexpensive consumables like gloves as C. Similarly, an IT department might treat servers and high-end devices as A items versus cables or peripherals as C. This prioritization helps improve inventory management efficiency by allocating resources where they matter most.

6. Standardize Processes and Train Your Team

Technology and analysis won’t get far without well-trained people and standardized processes. Develop clear procedures for all inventory-related activities – receiving shipments, updating records, picking and packing orders, handling returns, etc. Document these workflows and ensure your staff are trained on them. By standardizing these processes across your organization, there will be fewer errors and less confusion regarding inventory transactions.

7. Integrate Inventory Data Across Your Organization

Siloed information can undermine even the best inventory efforts. Make sure your inventory management system is integrated with other key systems like your ERP (Enterprise Resource Planning), procurement system, sales/order management, and finance software. By breaking down data silos, you enable more informed decision-making and prevent the errors that occur when systems don’t talk to each other. A unified view of inventory across the organization also helps different departments collaborate: for example, sales can see what’s in stock, and operations can see upcoming sales promotions that might spike demand.

Each of these tips can help streamline your inventory operations. Start by assessing which areas are your biggest pain points, then apply the relevant strategies. Inventory management improvement is an ongoing process, but with modern tools and a commitment to best practices, even large and complex organizations can turn inventory from a headache into a well-controlled, optimized part of the business.

How Asset Panda Can Streamline Your Inventory Management

Understanding how to improve inventory management is just one piece of a larger puzzle. To bring an optimal inventory management plan to fruition, you need the right technology partner. Asset Panda can help.

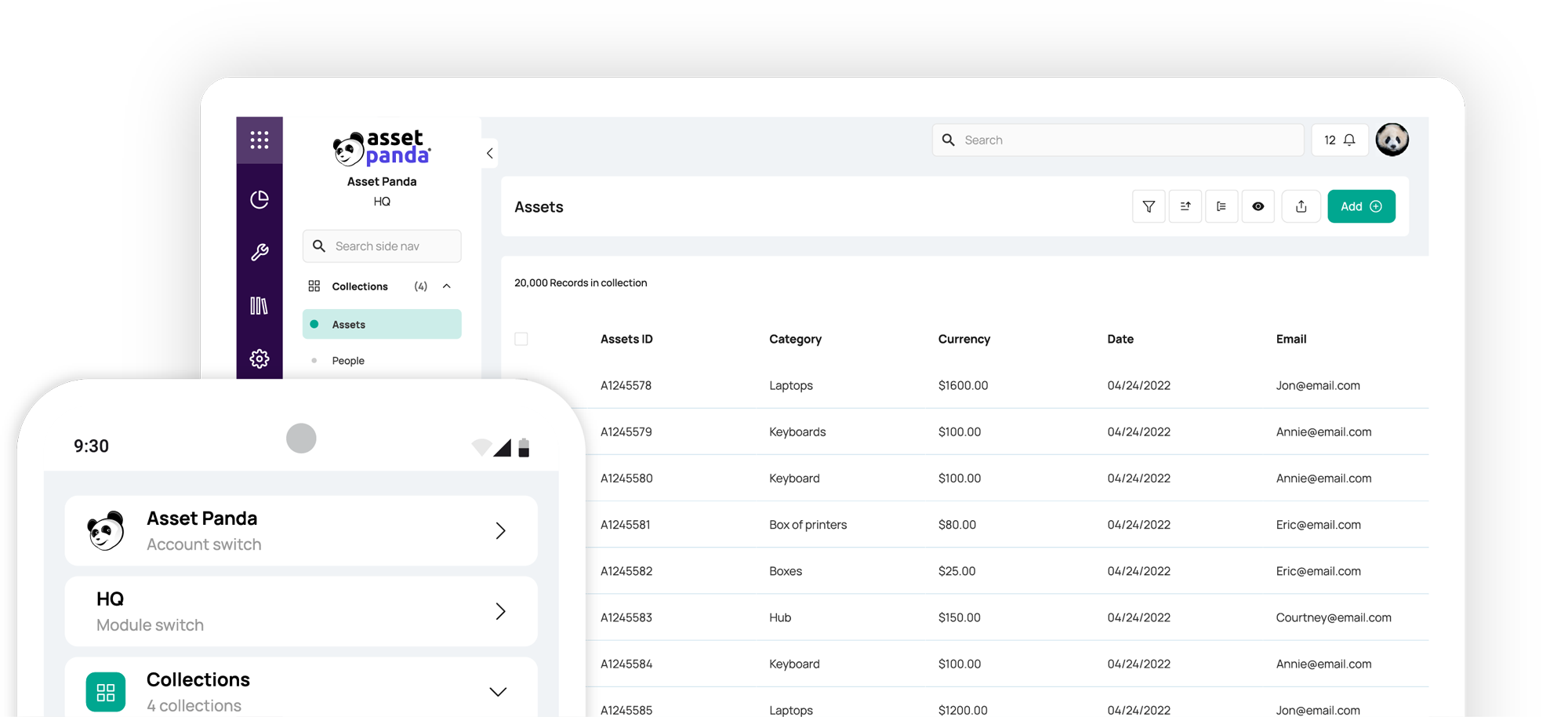

Asset Panda is a cloud-based inventory and asset management platform designed to help organizations like yours implement the best practices outlined above. With Asset Panda, you can gain full visibility into your inventory in real time across multiple locations and departments. Our robust web and mobile apps enable you to track inventory from anywhere, and built-in barcode scanning allows employees to perform audits or update stock levels with a quick scan right on their smartphone.

With Asset Panda's highly configurable platform, you can build workflows that match your existing processes for fast time to value. Whether you’re in manufacturing tracking machine parts, in healthcare managing medical supplies, or in IT logging hardware assets, our easy-to-customize software has you covered.

Ready to transform your inventory management from a source of stress into a strategic advantage? Schedule your personalized Asset Panda demo today.

Take Control of Your Assets

A personalized demo is just one click away.

Related News & Press

Learn more from a solution specialist

Schedule a demo to find out how you can transform your workflows with Asset Panda Pro

Contact our team at (888) 928-6112