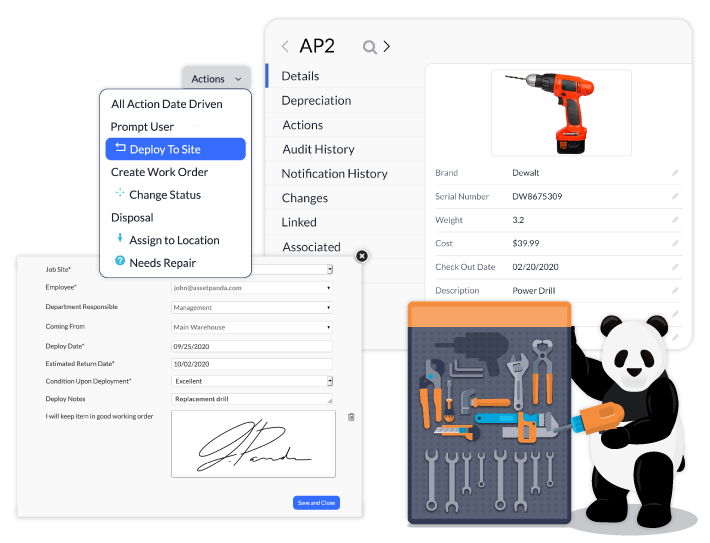

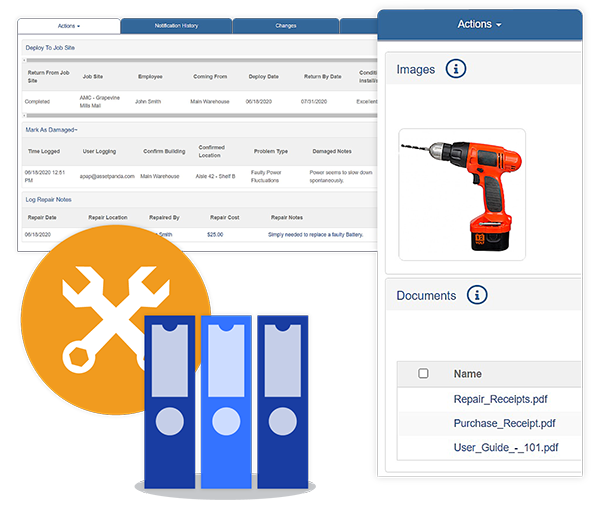

Gain visibility into the lifecycle of your tools

Increase operational efficiency with asset lifecycle management

Get insight into the full history of your tools and assets with our comprehensive tool tracking software. Access detailed records with warranty information, repair history, and more to optimize asset utilization and reduce potential downtime. With robust records and reports, you can keep your tools in working order longer and avoid overspending.

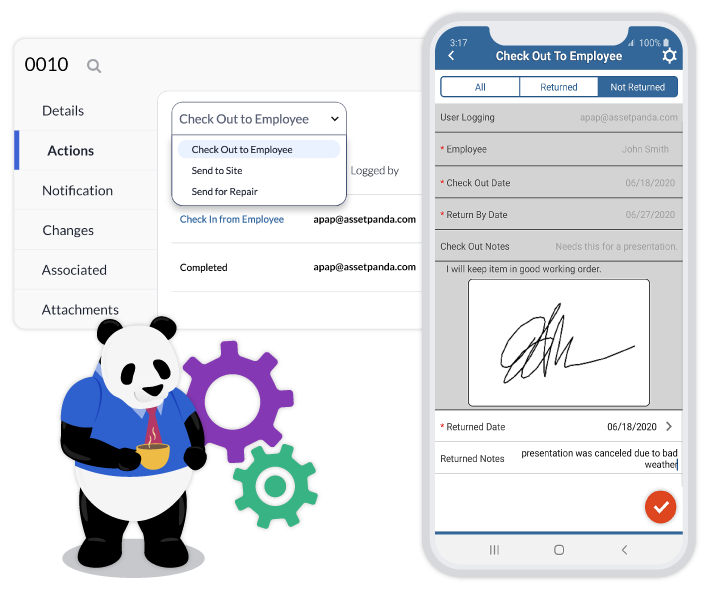

Track tools from anywhere

Easily track and manage tools using our mobile app with built-in barcode technology

Empower your team to check out tools or request repairs directly from the job site with our easy-to-use mobile app with available offline mode. Generate and print your own barcodes or QR codes from Asset Panda and scan them with your mobile device – no third-party scanners required.

With our mobile tool inventory software, you can uphold your workflows from anywhere and help your team save time and improve data accuracy.

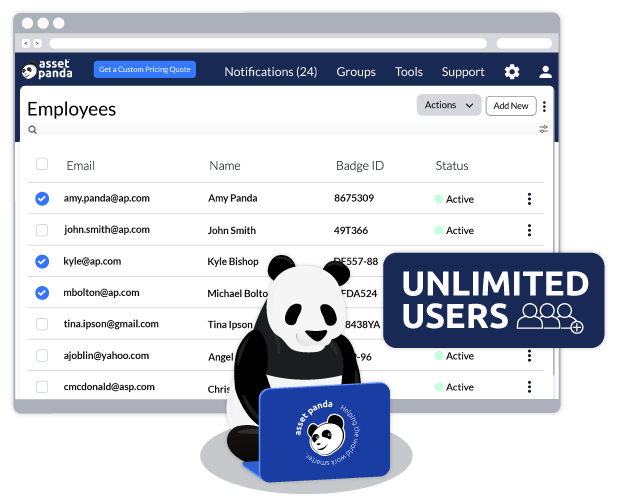

Manage everything in one platform

Create a single source of truth for all your tools, workflows, and employees

Track everything that matters to your business in our highly configurable tool tracking software. Manage various types of assets, build your custom workflows, and keep an updated employee directory in one centralized platform.

Add your entire team to your tool inventory software with unlimited users and assign custom user permissions for increased accountability and security.

Unlimited Users

Get your entire team on the same page and set custom user permissions.

Fast Time to Value

Achieve high user adoption and ROI with our intuitive interface.

Full Lifecycle Management

Track the full history of your tools with comprehensive records and reports.

Useful features for tool asset management

Improved Visibility for Tools on the Move for Renfro Electric

“Signing out tools is a breeze thanks to Asset Panda’s mobile app. Our field users...can quickly and easily sign tools in and out. There is no more guessing as to where assets are or interrupting phone calls to employees in the middle of their work to see who has what.”

Kyle Adair

PM/Estimator

Enhanced Accountability Saves Track Utilities Hundreds of Hours Each Year

“Since Track Utilities has started using Asset Panda we are now able to keep tools with the appropriate crews and make sure they are returning tools after being used. The ability to keep people accountable and take ownership of the tools they work with has paid for the cost over and over again”

Brian Bruni

Asset Management

Tracerco Gets Better Access and Time Savings

“...Asset Panda has allowed many people to contribute to a system that was once managed manually by one person. I estimate that we're saving three hours a day by using Asset Panda for our asset tracking efforts.”

Justin Tippit

Operations Manager

Mobile Access and Custom Reporting For Ace Avant Concrete Construction Co's Tools

“The customization of the software specifically for our needs is very important. We can pull customized, detailed reports on any piece of equipment in the system from its check in/check out status to a complete maintenance history.”

Ricardo Hernandez

IT Technician

Related tool tracking resources

Learn more from an Asset Panda expert

Get a FREE consultation with an asset tracking expert to find out how you can transform your asset tracking.

Contact our Sales Team at (888) 928-6112